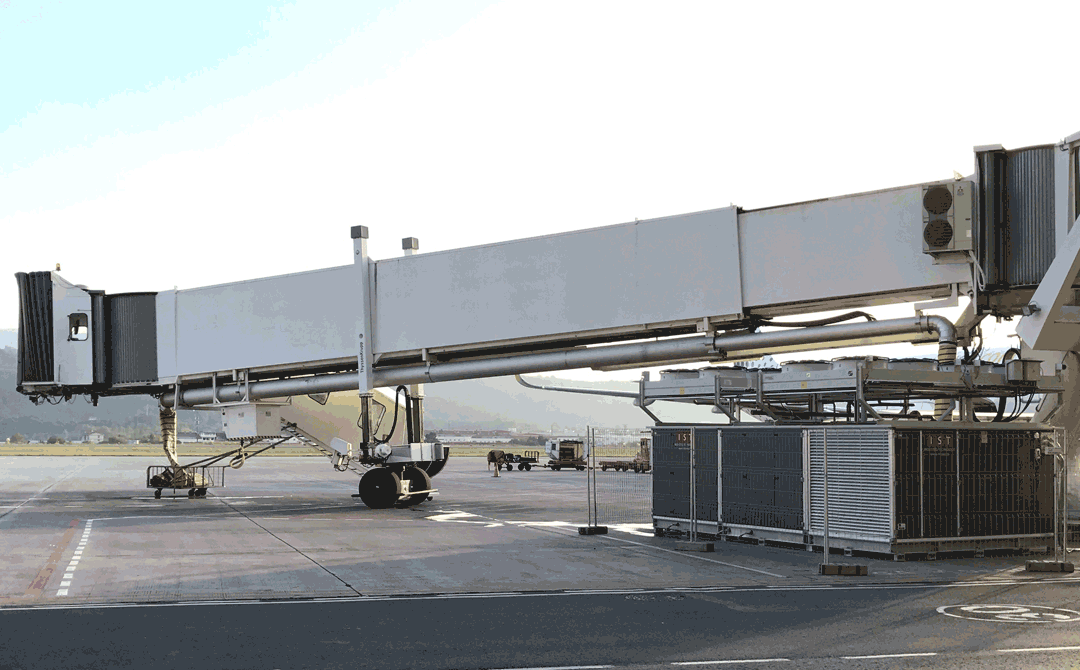

THE NEW COOLING CONCEPT

Under rated conditions the ISTinox PCA unit produces the required air flow rate (15’000 kg/hr) and cools it constantly to the required temperature. In order to optimize the cooling of the aircrafts, the new DXi unit has two cooling coils to ensure continuous cooling of the aircraft even during defrosting.

In addition, the new refrigeration concept also optimizes the regulation of the defrost cycle. De-icing only takes place when it is necessary and, contrary to existing systems, it is not timed but measured. The de-icing cycle takes place approximately every 50 minutes and lasts around 6-8 minutes. During the defrosting cycle, the first compressor runs continuously; thus, the temperature of the PCA does not climb to values higher approx. 5,5°C during the defrosting cycle and continuous cooling of the aircraft is guaranteed.

CONTINOUS COOLING DURING DEFROSTING

During defrosting the unit outlet temperature generally remains below 0°C, except for a short period of approx. 5-6 minutes, where the maximum outlet temperature peaks at approx. 5,5°C.